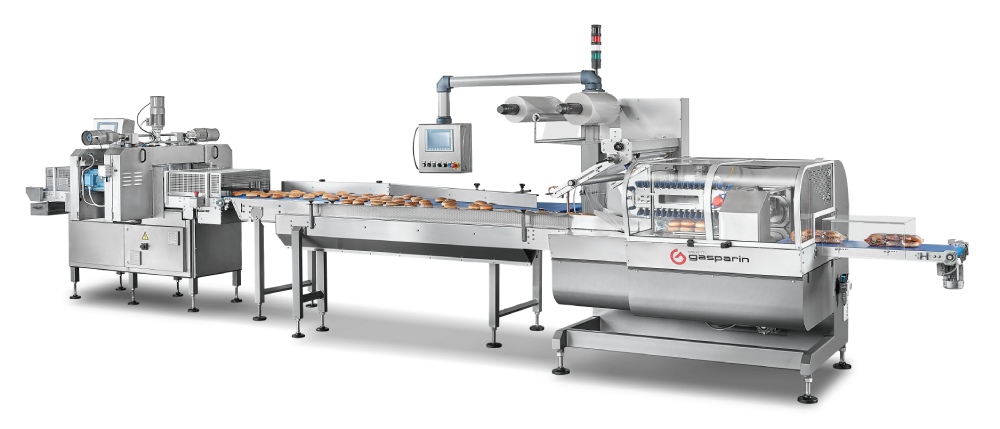

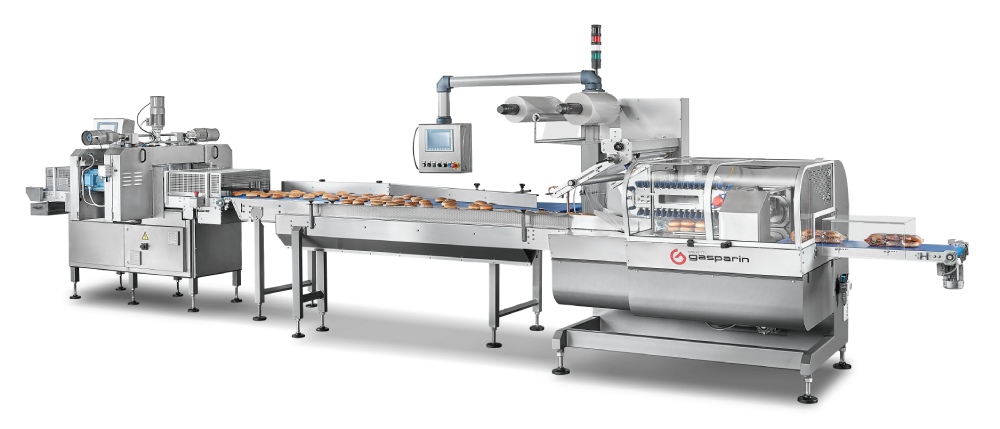

Slicing and flow-wrapping lines can be composed and customized in different ways to meet the customers’ different requests and needs with the possibility to personalized the plant combing in line ...

Slicing and flow-wrapping lines can be composed and customized in different ways to meet the customers’ different requests and needs with the possibility to personalized the plant combing in line ...

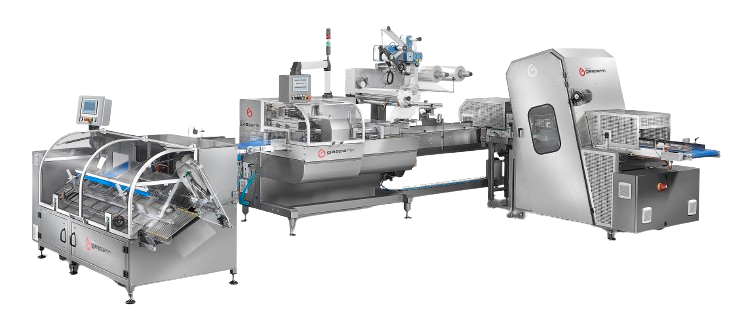

The automatic bagging line allows the bagging at high speed of the products after the slicing, automatically. By combining the bagger machine to a slicer is composed an automatic solution, ...

Specially designed for slicing baguettes, buns and other round rolls horizontally in half, the Zip is the perfect companion for sandwich shops and other snack outlets. ...

A revolution has been born in the bakery for a few years: Offer the customer the possibility of adapting the thickness of the slice to the different types of bread. ...

The Eco+ 450 is the best seller in the range of point-of-sale slicers. Configurable at will, it adapts to your needs. Discover all that it can offer you. It can ...

Tin Bread, Bread Loaf, Baguette Sour Dough, BunTin Bread, Bread Loaf, Baguette Sour Dough, BunThe Pico manual slicer is the ultimate access slicer. A concentrate of JAC technologies for a ...

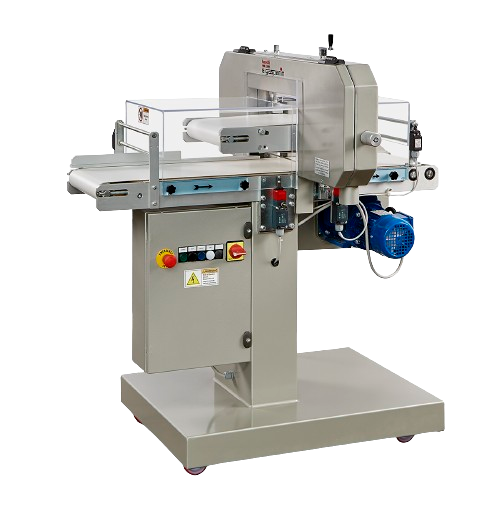

Horizontal continuous band blade slicer Suited for the total horizontal slicing of products Single continuous band blade cutting head mounted on balanced pulleys for excellent adherence Lateral blade guides in ...

Continuous band blades slicer Suitable for the bread slicing at high speed Cutting head with continuous blades mounted on two rollers rectified and balanced for a perfect adherence on the ...

Vacuum cooling: innovating the art of baking Vacuum cooling offers new possibilities for the preparation of bread and bakery products. After all, our vacuum cooling solution is not just a ...

This is a top-class four-chamber machine for cake production! It has four heads, e.g. two for dark dough, two for dark and light dough, and two for filling, e.g. cream ...

Page [tcb_pagination_current_page] of [tcb_pagination_total_pages]