The Changing Landscape of Indian Baking

India’s baking industry is undergoing a transformation fueled by changing consumer demands, growing export opportunities and increased competition. As the market evolves, bakeries across the country face one pressing question: How do you stay ahead in a rapidly changing landscape? The answer is clear – AUTOMATION.

In the fast-paced world of commercial baking, where quality, consistency and speed are paramount, manual methods are no longer enough. Let’s explore why Automation is the future of Indian baking and how you can partner with Autobake to lead the charge with its world-class solutions.

1) Scaling Up: The Need for Speed and Precision

The Indian baking industry is booming, with consumers demanding a more comprehensive range of products – from traditional bread to artisanal cakes and cookies. But with this growth comes the need for increased production capacity, faster output and consistent quality. Manually-operated bakeries struggle to meet this demand, especially during peak seasons.

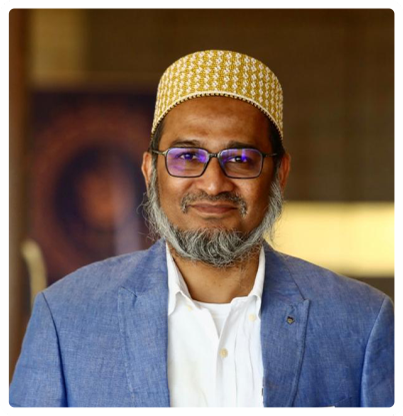

How Can Automation Help Meet Growing Market Demand?Automated systems can produce thousands of uniform products per hour, ensuring bakeries meet growing market demand without compromising quality. Autobake’s semi and fully-automated lines, powered by Koenig’s advanced technology, offer precision in critical processes like dividing and rounding dough, making them ideal for large-scale operations. Mr Junaid Khan, owner of All Fresh Bakery in Aurangabad and co-owner of Delite Oven Fresh Deluxe Bakery, shares his experience and expresses his satisfaction with the Koenig Mini Rex Multi machine. “It’s a must for every bakery,” he remarks, adding that “the machine has been so efficient that I have now ordered the 4-pc template to produce smaller bread products.” He explains that this system has allowed his bakery to cover their entire range of products, including buns, burgers, pav, doughnuts, and rolls. With such versatility and efficiency, Mr. Khan highly recommends Koenig’s equipment for any bakery looking to scale and meet market demands.

2) Competitive Edge: Stay Ahead or Fall Behind

In today’s cut-throat market, efficiency is everything. The ability to produce more in quick time, using less space while maintaining product quality, gives bakeries an edge. Manual methods, on the other hand, are prone to human error, leading to inconsistent product quality and slower output.

What makes Automation essential for staying competitive?Automated lines eliminate the risk of inconsistency and reduce downtime caused by human fatigue. Autobake’s Hasborg Trio machine exemplifies this by enabling bakeries to produce a wide variety of cookies, almost all types and variations, without needing multiple machines, thus increasing flexibility and reducing operational costs. According to Rafal Mucha, Owner of Hasborg, their commitment to innovation drives them to design machinery that enhances production efficiency, helping businesses remain competitive in an ever-evolving market. He further explains, “The Hasborg Trio machine offers unmatched flexibility, allowing bakeries to produce diverse cookie types on a single line, drastically lowering the need for additional equipment and significantly reducing operational costs.” Additionally, Mucha emphasises their dedication to sustainability, noting that “energy-efficient transmissions and motors ensure that our machines are both eco-friendly and highly productive.” This alignment of modern technology with environmental responsibility gives bakeries the tools they need to lead the industry.

3) Hygiene and Product Shelf Life: Meeting Global Standards

With rising awareness about food safety and hygiene, customers and regulatory bodies alike are demanding higher standards. Manual handling of dough and ingredients poses significant hygiene risks, leading to shorter shelf life and potential product contamination.

Why is Automation critical for maintaining hygiene and extending shelf life?Fully automated systems minimise human contact, ensuring hygienic production processes and contributing to extended shelf life for baked goods. Autobake’s range of Mono equipment, known for its cutting-edge depositor systems for cakes and cookies, ensures that hygiene standards are maintained while delivering precision in every batch. Yusuf Patanwala, Founder & CEO of Autobake, explains that their machines are designed for quick assembly and disassembly, making them easy to clean and maintain. “The lightweight parts make the equipment operator-friendly and allow for deep cleaning,” he says, emphasising the importance of maintaining hygiene. He also highlights that Mono’s equipment is trusted in over 100 countries, adhering to the highest international standards. According to Yusuf Bhai, “Our machines are simple to operate, efficient on a single-phase system, and built to last, capable of running for 15-20 hours a day with a lifespan of 25+ years. Some older models in India have been running for over 40 years, a testament to their quality and durability.”

4) Product Diversity: Catering to the Modern Consumer

Today’s consumers want variety. From artisanal bread to gluten-free and vegan options, the demand for diverse products is rising and will continue to be the trend. For bakeries looking to cater to this growing demand, flexibility and diversity of product range will be critical.

How does Automation support product diversity?

Automated systems allow for easy switching between products without the need for significant manual intervention, enabling bakeries to offer a wider variety of products. Autobake’s versatile machinery supports the production of everything from traditional bread to high-end cakes and cookies, all with minimal downtime.

Autobake’s Pivotal Role in Shaping India’s Baking Future

For over 2 decades, Autobake has been the trusted partner for Indian bakeries seeking to automate and modernise their production lines. By collaborating with global industry leaders such as Koenig, Hasborg and Mono, Autobake has consistently brought world-class baking solutions to India. Their unwavering commitment to quality and innovation has enabled hundreds of bakeries across the country to scale their operations and stay competitive in an increasingly dynamic market.

Mr. Shashank Chokhani and Mr. Ajay Kariwal, Managing Directors of Kanhai Foods Pvt. Ltd., Ahmedabad, have witnessed this transformation firsthand. They explain that Autobake’s expertise has significantly improved their plant’s effectiveness and introduced modern technologies optimising their production systems. “We have been associated with Autobake for nearly 5 years now, and the insights they bring to the table are amazing,” they mention. They further elaborate that “the equipment from Koenig and Mono offers remarkable flexibility, allowing for a wide range of product possibilities,” demonstrating Autobake’s ability to cater to diverse needs within the baking industry.

Don’t Wait to Automate with Autobake

Bakeries that fail to embrace this shift risk being left behind as the industry moves towards greater efficiency, hygiene and product diversity. With Autobake’s world-class partnerships and solutions, you can scale your operations, meet global standards and stay ahead of the competition. The future is here. Automate with Autobake and ensure your bakery’s success in the modern era of Indian baking.

Want to know how Autobake can transform your bakery?

and take the first step towards the Baking Automation Revolution.