Human Resources will always be an asset, provided they do what they are meant to do! Over the years, employees are often underutilised or burdened with tasks outside their job description. This mounting frustration leads to burnout or attrition, pressures the owner or management, and significantly reduces product quality and business performance.

The evolving Indian baking industry is no different, and traditional labour-dependent processes are becoming increasingly inefficient, impacting profitability. Bakeries that rely on manual labour for critical tasks such as dough mixing, dividing, rounding, slicing and packaging face numerous challenges – from inconsistent output and hygiene risks to rising labour costs. As bakeries struggle to meet the growing demand for products like pav, buns, cookies and cakes, the need for reliable, automated solutions has never been more pressing.

Automation is emerging as the ultimate answer to these workforce headaches. Autobake’s advanced European machinery and turnkey solutions are helping Indian bakeries address labour overdependency issues to reduce costs, streamline operations and maintain the highest levels of quality and consistency.

The Challenges of Labour Dependency in Indian Bakeries

– Inconsistent Output

Manual processes are prone to variability. Even experienced workers cannot guarantee uniform product quality with each batch. Size, shape and texture variations are typical, especially with popular products like pav, buns and cookies. This inconsistency can impact customer satisfaction and brand reputation.

– Hygiene Risks

Manual handling of dough/batter and finished goods introduces hygiene risks. In today’s health-conscious market, customers expect high standards of cleanliness. Manual packing of products like bread and cakes increases the likelihood of contamination, which can lead to product recalls and damaged credibility.

– Labour Shortages and Rising Costs

The bakery industry is experiencing a labour shortage, and the cost of hiring skilled workers continues to rise. This is particularly challenging when bakeries need labour for tasks such as dough mixing, dividing, rounding and packaging, which are highly time-consuming and labour-intensive.

Main Areas of Manual Usage in Traditional Bakeries

In traditional setups, the following tasks are typically performed manually, leading to inefficiencies:

– Dividing and Rounding of Dough

Dividing and rounding dough for pav, buns and rolls is a repetitive and labour-heavy process that often results in inconsistent sizes. Manual handling also increases the likelihood of errors and waste.

– Hygiene Issues with Manual Packaging

Products like bread, buns and cookies require hygienic packaging to maintain freshness. Manual packing, however, increases the risk of contamination, which is a significant concern in today’s market.

– Loading and Unloading

In traditional bakeries, loading and unloading trays or trolleys into ovens is another time-consuming task that requires substantial manual effort. It can slow down production and lead to inconsistencies in baking times.

Automation: The Ultimate Solution to Labour Challenges

Autobake’s advanced Automation solutions tackle these labour challenges head-on, offering a comprehensive range of machinery and systems designed to reduce manual effort, ensure consistency and boost overall production efficiency.

– Dividing and Rounding Automation

Autobake offers Koenig machines that automate the dividing and rounding process for products like pav, buns and rolls. These machines guarantee uniformity and reduce waste, ensuring consistent size and shape with every batch.

– Precision Mixing and Depositing

Autobake’s Mono Depositors handle large volumes of dough/batter, ensuring even consistency for products like cakes, muffins and cookies. These machines eliminate the variability caused by manual work, providing a uniform product across numerous baking batches.

– Automated and Hygienic Slicing and Packaging

For products like bread loaves, Autobake offers The Italian specialist since the 1960s – Gasparin, for their automatic Slicing and Packaging Solutions. The precision of these machines ensures that each slice is uniform, minimising the risk of contamination. With their streamlined process, products like cakes, cookies and buns are packaged in a controlled environment, maintaining hygiene standards and ensuring product freshness.

– Loading and Unloading Automation

Automating loading and unloading allows bakeries to increase production speed without compromising on quality. By automating these manual tasks, bakeries can optimise baking times and reduce the risk of human intervention and error.

Real-World Impact: How Indian Bakeries Are Reducing Labour Costs and Increasing Output

Many Indian bakeries have already shifted to Automation, reaping the benefits of reduced labour costs and increased output. There are many examples where replacing manual dough mixing and dividing processes with Koenig, Classic Rex has led to a 30% increase in production efficiency. Bakeries generally see at least a 25% reduction in labour costs, allowing them to invest in scaling operations and expanding their product range to include puffs, kulcha and pizza bases.

“After buying the Koenig machine – Classic Rex, our production increased 5 times! Since partnering with Autobake, our production and processes have all become considerably automated, leading to consistent production, better hygiene and superior product quality. Contrary to popular perception, Automation has actually made it possible to streamline our workforce and increase our employee strength due to our rising market demand.”

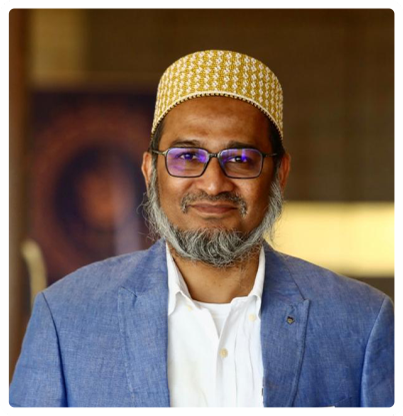

– Ajay Kariwal, Kanhai Foods Pvt. Ltd., Managing Director – Ahmedabad

Consultancy and End-to-End Solutions from Autobake

In addition to machinery from world-class industrial baking line manufacturers, “Automate with Autobake” offers comprehensive consultancy services that guide bakeries through the Automation process. Whether it’s designing a new facility, optimising existing production lines, or selecting the right equipment for specific needs, Autobake provides tailored solutions that ensure a seamless transition from manual to Automation. We are the ideal partners for Indian bakeries looking to embrace Automation and streamline their operations.

Automate for a Better Future

The future of baking lies in Automation. Automate With Autobake and secure your bakery’s competitive edge.

Contact our experts for a Free Consultation. Don’t wait for issues to arise. Automate With Autobake will assist you in equipping your bakery with automated solutions and elevate your hygiene standards to a global scale.