In a country as diverse as India, the baking industry is crucial to its food landscape. However, the journey from manual methods to automated systems has been slow for many businesses. While rich in heritage, traditional baking processes often limit the potential for scalability, consistency and quality. In today’s fast-paced market, those who fail to adapt to modern technologies risk falling behind.

Autobake is at the forefront of this transformation, helping Indian bakers transition from labour-intensive manual operations to high-efficiency automated systems with the finest European machinery. By embracing Automation, bakeries nationwide are experiencing tangible improvements in both productivity and quality, ultimately taking their businesses to the next level.

The Limitations of Manual Baking Processes

Manual baking, while traditional, comes with several inherent challenges:

– Inconsistent Product Quality

In manual operations, the risk of variation between batches is high. Even the most skilled bakers cannot guarantee uniformity in size, shape and texture when relying solely on human hands. This inconsistency can affect the overall product quality and customer satisfaction, mainly when producing items like pav, kulcha and burger buns.

– Inefficiency in Scaling Operations

As demand grows, manual processes become less feasible. The labour-intensive nature of manual baking in items such as pizza bases, puffs and doughnuts makes scaling production complex, often leading to longer working hours, increased costs and higher chances of error.

– Labor Costs and Availability

The bakery industry faces labour shortages, and manual labour costs are rising. With an overreliance on human resources, bakeries struggle to maintain production efficiency and keep pace with competitors.

The Autobake Difference: Automating the Future

Autobake offers many solutions to these challenges with its range of advanced European machinery from world-class brands like PFM, Koenig and Hasborg and futuristic bakery solutions from super-advanced technology providers like Weber and Tagliavini. These automated systems and hi-tech solutions bring numerous benefits to Indian bakeries:

– Consistency and Precision at Record Speed

Autobake’s automated lines ensure consistent quality across every batch, eliminating the risk of human error and long hours of waiting time. Weber Vacuum Cooling machines can cool up to 160 kg of baked goods in under 8 minutes, reducing the cooling time of sourdough bread, ladi pav and croissants by a whopping 97%!

– Maximise Space and Save on Energy Costs

Automation can save on factory floor space and energy, thus reducing the capex and operational costs, positively impacting bottom lines. The Rotovent Deck Oven from Tagliavini is exceptionally compact, flexible and highly productive. It can reduce energy consumption by 30% compared to traditional ovens, increasing profitability dramatically while enhancing product quality, consistency, texture and taste, be it cakes, cookies or bread.

– Reduced Labor Dependency

By reducing the need for manual labour, Autobake’s machinery lowers operational costs and minimises the risk of production downtime due to labour shortages. Automated systems enable bakeries to perform with fewer workers, streamlining operations and freeing up resources for other areas of the business.

– Streamlining Operations

From dough dividing and rounding to depositing and baking, Autobake’s machines are designed to handle multiple tasks on a single production line. This streamlined approach reduces operational complexity and ensures faster, more efficient output.

Success Stories: From Manual to Automation Mastery

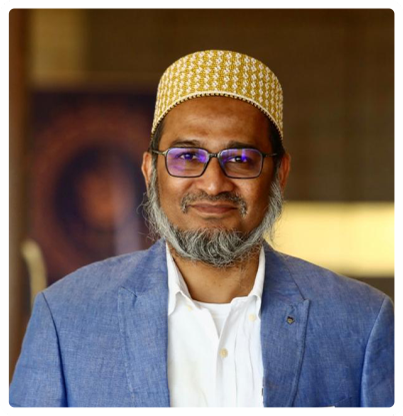

Many Indian bakeries have already experienced the transformative effects of Automation. One such success story is Atul Bakery. By partnering with Autobake, they completely redesigned their production process for celebration cakes, cookies, khari and rusk, significantly reducing labour and improving product quality. Their ability to swiftly adapt to automated solutions allowed them to scale efficiently, expanding to over 250 outlets across India and exporting to 17 countries. Atulkumar Vekariya, Managing Director of Atul Bakery, highlights that switching to Automation improved consistency and helped the company meet higher demand without the stress of manual processes and labour. It showcases how Autobake’s unique solutions have helped bakeries improve efficiency, scale operations, and reduce dependence on manual labour.

Shaping the Future of Indian Baking

Our vision for the Indian bakery setup is “Automate with Autobake.” It represents the future of Indian baking – The fellowship of bakery owners and service providers who can evolve the commercial bakery industry and move towards Automation jointly. It paves the roadmap for businesses to thrive and leave a mark at a global level. Autobake’s commitment to innovation ensures that bakeries can embrace modern technology without sacrificing quality.

By offering cutting-edge European machinery, tailored service and 24×7 troubleshooting support, Autobake is helping the Indian baking industry with the Automation advantage of mastering efficiency, consistency and innovation.

Be the Change that you want to see in the Indian Baking Industry

The transition from manual to Automation isn’t simple, but it’s not overly difficult either. Autobake equips bakers with the tools to streamline operations, reduce costs, and gradually upgrade technology and processes to produce top-quality products consistently. Automate with Autobake now!

Contact our experts for a Free Consultation. Don’t wait for issues to arise. Automate With Autobake will assist you in equipping your bakery with automated solutions and elevate your hygiene standards to a global scale.